Digital Twin

3D-MODEL & IOT & AR-VR DEVELOPMENT

MISSION : CONNECTING REAL WORLD TO VIRTUAL WORLD WITH REAL TIME DATA

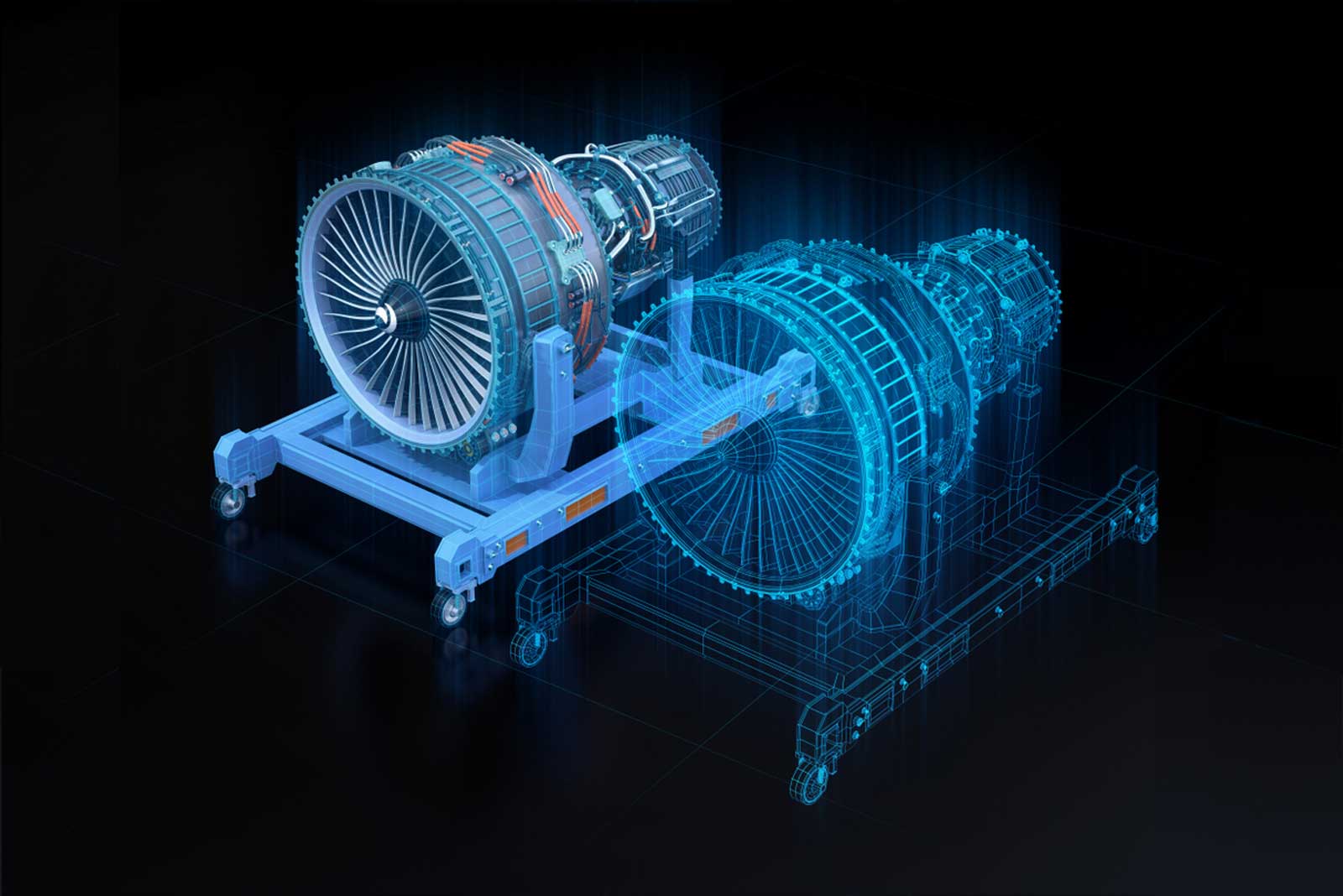

DIGITAL TWIN

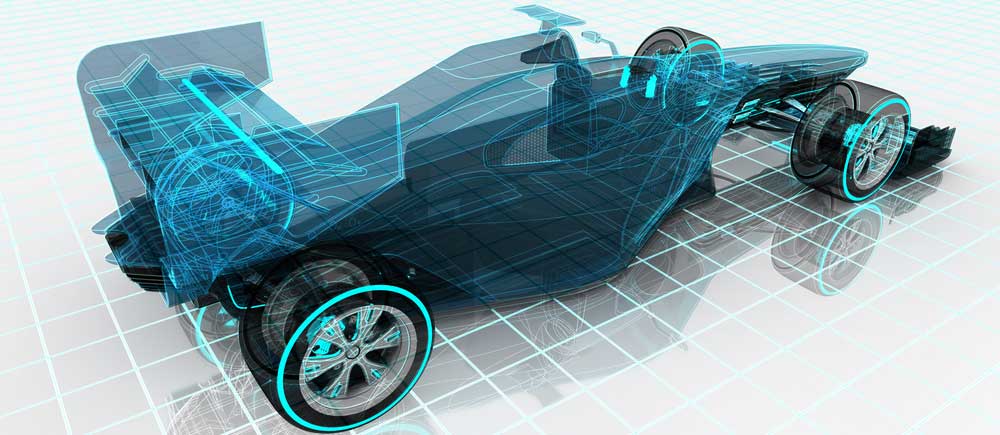

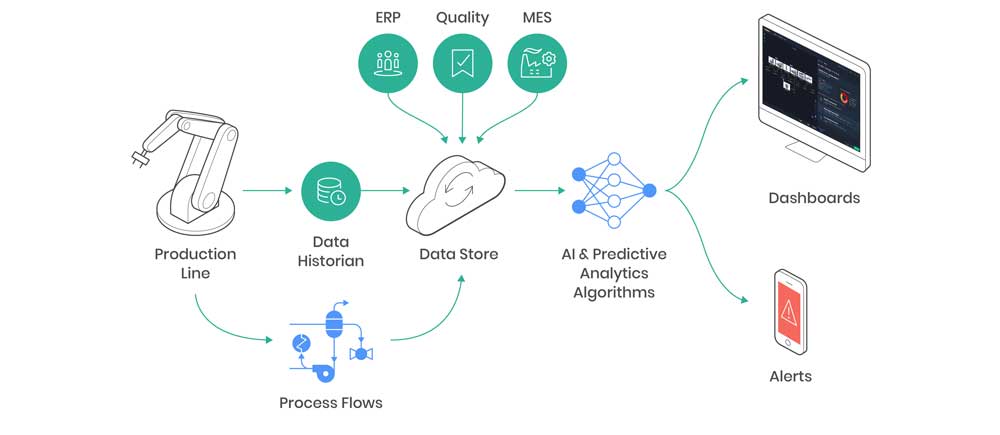

A digital twin is a digital replica of a physical entity and involves creation of a virtual model of a process,

product or a service. Digital twins integrate 3d-modelling, IoT, AI, and Analytics and therefore enables a connection between the physical entity and the digital replica. This pairing of physical and virtual worlds allows to collect real-time data, perform analytics, edge computing therefore to provide predictive maintenance, prevent downtime, identification of problems before they even occur, remote-monitoring, future planning using simulations, and automation to take corrective actions.

Our Project

Project part-1

Project part-2

Oculus version

DIGITAL TWIN for your industry

Product development

SALES AND MARKETING

PREDICTIVE MAINTENANCE

TRAINING AND SIMULATION

REMOTE MONITORING

AUTOMATION